Breaking News | Maxic Launches a dToF Sensor Integrating EEPROM: MT3805SD

-

Release Date2025-11-03

-

Page View871 times

DToF is rapidly expanding into diverse application fields, each has unique performance requirement. Robotic vacuum cleanerdemands short-distance measurement and high precision across total reflection; smart bathroom device priorities low power consumption; while smartphone’s autofocus requires long distance measurement range. Consequently, tailored algorithm firmware and calibration solutions are required to address the specific needs of different scenarios.

Traditional dToF solutions face significant constraints as it stores algorithm firmware and calibration parameters in the host. This approach not only occupies host memory but also rigidly binds calibration parameters to specific device.MT3805SD innovatively breaks these limitations by integrating EEPROM. It allows on-chip storage and online update of algorithm firmware and calibration parameters. The chip can call the calibration parameters directly, greatly saving the system memory of algorithm firmware and simplifying following calibration processes, enabling more flexible adaptation to various application scenarios.

Maxic's newly launched dToF sensor, MT3805SD, adopts advanced 55nm dToF process and integrates EEPROM, delivering both core performance and application convenience. The chip features ultra-low power due to its self-developed SPAD and corresponding process, and its built-in 8KB EEPROM supports on-chip storage and frequent update of algorithm firmware and calibration parameters.

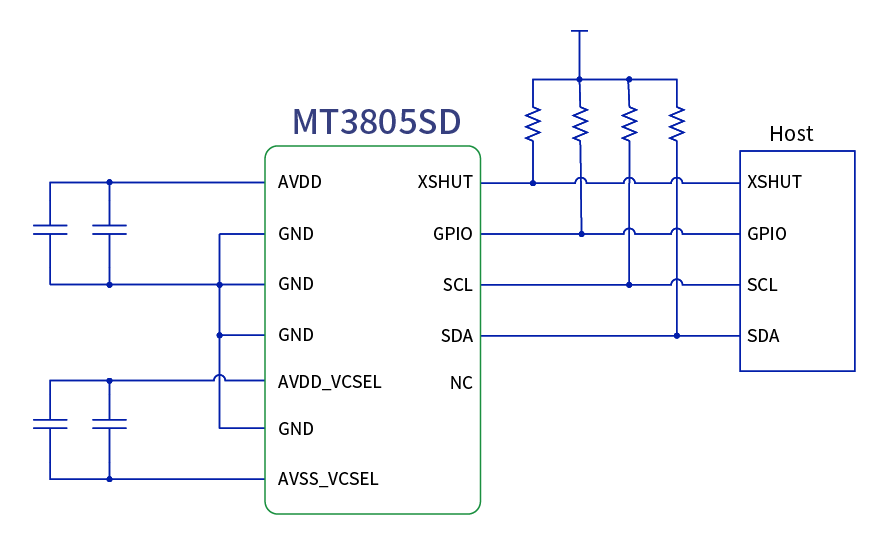

As integrating SPAD, algorithm processing module, Cortex-M0 core, 940nm VCSEL, and an optical filter, MT3805SD is well-suited for a wide range of applications—such as distance measurement and obstacle avoidance in robotic vacuum cleaner and lawn mowing robots—providing an efficient and compact intelligent sensing and ranging solution for end-use scenarios.

All-in-one module incorporating light source, optical filter, and receiving process module in OLGA12 package

M0 core with tailored algorithm for diverse scenarios

Integrates 8KB EEPROM for storing algorithm firmware and variable calibration parameters

Precise ToF measurement: 2mm~5m distance measurement with less than 4% error

Integrates temperature sensor for real-time temperature compensation, ensuring accuracy under varying temperature conditions

Supports 3.3V/1.8V/1.2V interfaces for broad compatibility

- Excellent EMI performance and sunlight resistance capability

Utilizing the process innovation and high-integration of the advanced 55nm dToF process, MT3805SD features high operating frequency and low power under the requirement of high-performance, low cost and high-reliability. The chip supports 3.3V, 1.8V, and 1.2V interfaces, making it compatible with 1.2V low-power new platform. It consumes <10μA current in standby mode, <20mA in ranging mode, and <18μA in operating mode, meeting the requirements of various low-power applications.

As the key innovation, the integrated EEPROM enables on-chip storage of algorithm firmware and calibration parameters, which removes the external MCU, greatly saving the hardware space and cost for end-users and simplifying design. Furthermore, the EEPROM supports multiple online programs, allowing flexible adaptation to parameter adjustments and algorithm iterations across diverse application scenarios, thereby greatly enhancing operational flexibility.

MT3805SD incorporates self-developed SPAD and corresponding process. As the key component of dToF sensor, SPAD’s performance determines the distance measure accuracy, response speed and power consumption of the sensor. After having refined calibration of the process parameters and structure optimization to the SPAD, the chip achieves significantly enhanced performance. This not only showcases the company's R&D capabilities in core component innovation but also strengthens the product's competitiveness in consumer electronics, robotics, and other applications, laying a solid technical foundation for the large-scale adoption of dToF solutions.

*The test results provided are based on laboratory conditions. Actual product performance may vary due to application environment and batch differences. Maxic reserves the right for final interpretation.

*The test results provided are based on laboratory conditions. Actual product performance may vary due to application environment and batch differences. Maxic reserves the right for final interpretation.Recommended News

-

2022-09-14

Grand launch | MT5785: 100W ultra-fast wireless charging and 18W reverse transmission

-

2022-08-05

Core leads new era | Maxic participated the Guangzhou International Lighting Exhibition 2022

-

2022-07-04

Maxic launched a fully integrated ultra-low power optical proximity sensor

-

2022-06-24

Maxic launched a high performance wired fast charging 20W~65W overall solution

Back

Back